Cosmic Ray Detection (Losada, Freeman, Lyon, Trant)

Experimental Overview[edit | edit source]

The purpose of this experiment is to setup a simple cosmic detection system, using scintillating paddles, with 4 Photo Multiplier Tubes (PMT)s and then to setup and understand a simple Data Acquisition (DAQ) system. The purpose of this setup is to detect incoming Cosmic Rays and to then setup a triggering system for our DAQ. This same approach is used for some particle detecting and data acquisition systems at Jefferson Lab, only on a much larger scale and way more complex.

Most of what we did in our experiment was in preparation for real 4 tube data taking. We began by configuring and understanding the scintillation process and PMTs, which were already setup from experimental setup that happened over the summer break of 2014. Next we setup the data acquisition system to accept one tube at a time in order to characterize each tube. The next step was to setup up the logic and triggering system to accept 4 tube operation.

Details for this process follows bellow on this wiki page.

Hardware Setup (Trant)[edit | edit source]

Hardware Description[edit | edit source]

DAQ Overview and Concept of Triggering[edit | edit source]

Perhaps an overview of what a DAQ is, and explanation of the idea of triggering on an event ... ? What are we describing below?

Linear Fan-in Fan-out(FiFo)[edit | edit source]

This module receives a signal from one of the four tubes then copies the signal into four outputs for us to use. this enables us to view the analog signal on the oscilloscope while sending it to the CFD to continue with processing the signal.

Constant Fractional Discriminator(CFD)[edit | edit source]

the CFD receives the signal from the Fifo and converts it from an analog signal to a digital signal. The digital signal can then be pushed through logic gates to give it some delay so it is easier to analyze.

Nim-ecl / ecl-nim Converter[edit | edit source]

(tony) This module is just a cable converter, the TI unit only accepts ribbon cables (ecl) so we must change cable forms to use it.

Trigger Interface(TI)[edit | edit source]

(Tony) This card is a special device manufactured by JLab to serve as an interface between CODA and the VME boards (QDC and TDC), it has a few purposes. Firstly, it serves as an anchoring point to allow automated addressing of the VME boards, meaning that if one is moved to a new slot, the system will automatically update it's read locations. Secondly, it serves as an event limiter. When an event causes a trigger, it is sent into the input of the TI, then the TI will emit a level 1 accept signal (L1A). This signal is what will then be sent to the gate of the VME boards to trigger data recording. The TI also sends out a busy signal(BSY) to prevent another trigger from interrupting the VME boards while the are recording an event.

Discriminator[edit | edit source]

The Lecroy Quad Discriminator generates precise logic pulses in response to its input exceeding a given threshold. Output pulses are of standard amplitude and of preset duration or proportional to the input rate. The threshold is a specific voltage of interest to the user, which can be set above some critical noise level and correspond to a certain level of integrated rates (coincidence events).

Charge to Digital Converter(QDC)[edit | edit source]

(Tony) This VME board is a DAQ module that integrates the charge of a raw signal over the entire period while it is receiving a trigger in its gate port. This will produce a numerical value between 0 and 3096 that is a ratio to the total charge of the signal.

Time to Digital Converter(TDC)[edit | edit source]

Table of Hardware (Freeman)[edit | edit source]

The following is a table of all hardware components used in the Data Acquisition ( DAQ ) system for our experiment.

| Model | Description | Data Sheet | User Manual |

|---|---|---|---|

| GE XVB601 | VME single board computer | XVB601_datasheet.pdf | |

| JLab TI Board | In house made trigger interface board | TI UM | |

| CAEN V792N | CAEN QDC card | V792 DS | V792 UM |

| CAEN V775N | CAEN TDC card | V775N DS | V775 UM |

| Lecroy 428F | Lecroy Linear Fan In Fan Out Card (FIFO) | 428 DS | |

| Ortec 934 | Constant Fraction Discriminator | 934 UM | |

| Lecroy 821 | Quad Discriminator | 821 DS | 821 UM |

| Phillip Scientific 755 | Quad Majority Logic Unit | 755 DS | |

| CAEN N638 | Quad Scaler and Preset Counter/ Timer | N638 DS | N638 UM |

| CAEN N1470 | CAEN High Voltage Power Supply | N1470 DS | N1470 UM |

| CAEN N638 | NIM-ECL Translator And Fan Out | N638 DS | N638 UM |

Setting Bias Tubes and taking 4 Tube Data[edit | edit source]

I think we need to say something about the difference between the configuration we had for characterization and what we have now. Tony also said he would do this section ....

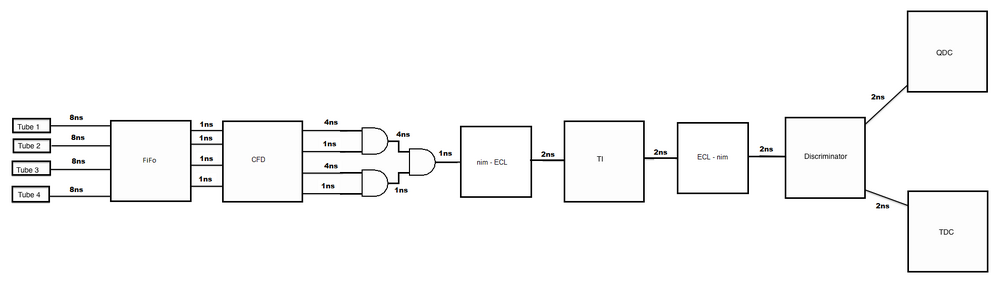

Diagram[edit | edit source]

The Diagram below shows the wiring of the system. every wire is labeled with it's delay and each module is described above.

Hardware Connection (Hesse,Davison,Kerver)[edit | edit source]

Make sure the CPU module is on the far left side of the VME crate, followed by the trigger supervisor, then the rest of the modules.

Connecting High Voltage[edit | edit source]

1. Preparing High Voltage[edit | edit source]

To remotely access and control the high voltage supply, open the terminal and become super user by typing "su" , followed by the super user password. Once a super user, type "minicom" in the terminal. The serial connection to the HV supply should already be set as the default device, so once minicom is open the terminal should display the controls for the HV. Otherwise, the voltage can be adjusted directly from the power supply by using the knob controller.

Hint: If the display for the high voltage controller does not appear within minicom type caen to show the voltage control.

Hint: If a connection cannot be made the correct USB output needs to be chosen: minicom usb1

Minicom alternative - CAEN HV interface (Freeman)

2. Attaching Cables[edit | edit source]

On the end of each PMT there is a connector labeled (HV) for high voltage. Here, securely fastened (HV) cables can be connected to the PMTs and linked with the power supply in separate channels. (Channels 0 to 3)

3. Polarity[edit | edit source]

Make sure that the polarity on the power supply is set to negative. If it is not, the polarity can be adjusted by removing the power supply, taking off its rear panel, and switching the polarity. (Refer to the power supply manual for further instruction)

Wiring Signal[edit | edit source]

All four PMTs are connected with signal cable to a Linear Fan-in Fan-out module. From there the input signal can be copied and have up to four output signal destinations. The outputs from all four PMT signals are then connected to a Constant Fractional Discriminator (CFD) with a 2nm signal cable. Signals 1 and 2 from the CFD then pass through a Quad four-fold logic unit set to a coincidence level of 2. Signals 3 and 4 are also then ran through the Quad four-fold logic unit, and the outputs from both are also anded in the Quad four-fold logic unit. This final output is then wired to an oscilloscope or and ADC unit for analysis.

Steps to Start Taking Data (Freeman)[edit | edit source]

Log on to jlabdaq computer, with the coda username[edit | edit source]

Start msqld database server[edit | edit source]

- type msqld in a terminal window

- More Details

- Warning if you neeed to kill or restart the db server you must do so by killing the process:

- From a terminal window type: ps wwwaux | grep msqld | awk '{print $2}' | xargs kill -9 &

Start CODA:[edit | edit source]

- You must be logged in as username coda, then type startcoda

- Killing CODA:

- When you are finished, just type killcoda

- To look at the code click, here

- When you are finished, just type killcoda

- For more details on what was done to install CODA and how to setup the CODA configuration, browse this section

Start the CAEN High Voltage, minicom window[edit | edit source]

- You must be logged in as the super user, type su into the command line.

- when prompted for a password, type in the root password.

- Turn on High Voltage to the Tube Channels that you want to power.

- For more details see previous section, Connecting High Voltage

Once CODA is Running and the Run Control GUI is up:[edit | edit source]

- Go to the title bar and select Configure.

- Select the Download Icon

- Select PreStart

- Now you can Start When Ready

Tube Characterization Scans (Freeman)[edit | edit source]

Introduction[edit | edit source]

In order to best set up our system for collection of cosmic data we must adjust the threshold (on the Ortec 934 CFD Card ) and the level of high voltage (HV) applied to the PMT using the (CAEN 1470). To understand what levels these two quantities should be set to we must perform some tube characterization scans (described below). We opted to perform the threshold scan first, then using the threshold we determined we could perform our HV scans. Once a scan was completed we could plot the logarithm of the rate (log(rate)) vs. the scan target (threshold or HV). We new that the scans would provide a double exponential pattern and that the first plateau would be appropriate operation level of our scan target.

In order to find the proper threshold, our first run, we adjusted the threshold on the Ortec 934 CFD Card. The next 4 sets of scans we adjusted the high voltage (CAEN 1470) and then let coda run for a fixed amount of time (600 s). This gave us some event count. By plotting the log(Rate) vs. Voltage we are able to characterize each tube and find at which voltages we get all noise and for which voltages we get peak signal.

Scans[edit | edit source]

Rate vs. Threshold Measurements[edit | edit source]

Our original plan was to scan through thresholds 100mV - 2000mV at 100mV steps and used a voltage of 1550 V . We began by adjusting the threshold, then let coda run for 1000 events. We recorded the start and stop time of coda. From this we are able to extract a time delta, and then calculate a rate. We also originally decided to only take this measurement with one tube.

We found very quickly that as we increased the threshold from 100mV, 200mV, and then 300mV that if we continued to use 1000 events it would take many hours to complete the upper thresholds. We decided to lower the amount of collected rates to 250 events. Equally as we raised the threshold to higher values we found that cutting off the max threshold was a good idea. We plotted and fit our data after we found the first few points. This allowed us to see an exponentially decreasing plot. With a threshold of 500mV we have, nearly, a zero rate. We decided to not go to any higher thresholds, but to fill in some of the gaps and took more data points from 150mV - 450 mV By plotting the log(Rate) vs. Threshold we were able to see a plot that has a linearly decreasing slope, roughly picking where the line crosses the y=0 we chose a threshold of about 250mV.

We assumed that we should set all of the thresholds to the same value, after taking data on one tube. After checking one of the other tubes and getting different results, it was observed that the threshold values should be measured and characterized for each tube.

Rate vs. Voltage Measurements (Losada)[edit | edit source]

To perform this scan we needed to set the threshold to a set amount and scan over a range of voltages. Based on prior knowledge (obtained from the threshold scan) we chose to run the scans at a threshold of 150mV and scan from -1300V to -2000V in 50V increments. To control the amount of time data was collected we used our timer/scalar (CAEN N1145). We set it up to count events for 600s per run. Once again we are looking to obtain the double plateau shape to determine the appropriate operation levels.

Error Analysis[edit | edit source]

The following errors were calculated and placed directly into the data files. See below for details in the error analysis.

Error in log[Event Count/ Time] (Vertical Axis)[edit | edit source]

- Using the Variance Formula we were able to calculate the propagation of uncertainty of the Log( # of events / time )

Where is the error in the number of events counted, and is the error in the time. The variable is the number of events counted, and it variable for time.

So, our equation becomes:

Note that we assume that there is no error in the number of events counted, an event is either counted or it is not. We took the error in time to be equivalent to 0.5 [ms], which is half the time smallest time scale of the CAEN N1145 Timer/ Scaler card. So our final uncertainty is equal to:

Error in Threshold Values[edit | edit source]

- Error in this measurment was dominated by the error in the multimeter measurment. The meter is a HT39. From the spec sheet:

Error in DC Voltage Measurment = +/-(%0.5 of Readback + 2 of the least signifigant digit)

Error in High Voltage[edit | edit source]

- Error in the High Voltage measurment is the error in the CAEN 1470 voltage. From the Spec sheet:

Error in the Readback Voltage vs Measured Voltage = +/-( %0.02 of Readback +/- 2[Volts] )

Results[edit | edit source]

Data Files[edit | edit source]

- Columns are:

- Voltage or Threshhold, Event Count , Voltage or Threshold Error, and Error in Log(Rate)

Threshold Scans[edit | edit source]

1. threshTube3.dat 2. threshTube4.dat

Voltage Scans[edit | edit source]

1. tube1.dat 2. tube2.dat 3. tube3.dat 4. tube4.dat

Root Macros[edit | edit source]

Macro for producing Log(Rate) vs. Threshold

Macro for producing Log(Rate) vs. Voltage

Graphs[edit | edit source]

- Used Root to create and save plots

Threshold Plots[edit | edit source]

1. threshold_tube3 1. threshold_tube4

Voltage Plots[edit | edit source]

1. tube1 2. tube2 3. tube3 4. tube4

Analyzer/ Reading Data Words (Lyon)[edit | edit source]

Description[edit | edit source]

What is analyzer and why do we want to read data words. Probably need to say something about root trees

Our Setup[edit | edit source]

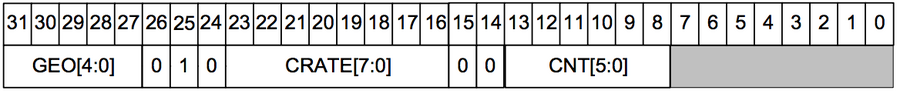

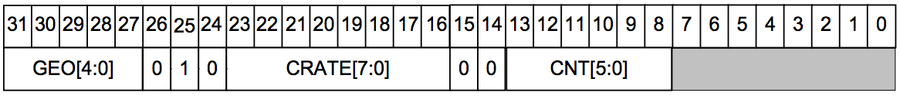

The image shown is how the data taken from this setup will appear. The data words in the image are organized in an order as follows: a run count word that tells the run number of the file, a header word of the QDC to tell how many data words follow(this will always be 16 words), the data words of the QDC, a header word for the TDC (0-4 words in cosmic setup), the TDC data words, and a closing word that tells the analyzer to stop parsing(daebd00d).

- For more information about decoding the output buffers, read the user manual pages:

Hex to Binary Conversion[edit | edit source]

These words are shown in hexadecimal (the 0x denotes a hex number), so first they are broken down into 32bit binary words. First off, a word is just a number for the computer, which means this will just be converting a number from one base to another. Hexadecimal numbers have sixteen different digits, which range from 0 to F. Binary numbers only have two digits, which are 0 and 1. Because sixteen is a power of two (specifically 2^4), so a hex number can be written as a four digit binary number. The chart shows the conversion from hex to binary and decimal.

Example[edit | edit source]

Here is an example of how to break a hex word down to bits. The given hex word is:

0xfa8004081

The ‘0x’ just denotes that it is a hex word, so we ignore it for conversion. Following the chart, f becomes 1111, 8 becomes 1000, 0 becomes 0000, etc… When you put them all together our final binary word becomes:

11111000000000000100000010000001

The word make-up[edit | edit source]

The run count word simply recalls the run number of the data. This is used for labeling purposes.

QDC Header Word[edit | edit source]

TDC Header Word[edit | edit source]

Starting from the left, the first five bits are the geographical location. We should always expect 11111 for this part because our location is constant. The next three bits denote the kind of word. A header word will read 010 and a data word will read 000. For the header word, the next eight bits denote the crate being used. Both the TDC and QDC are operating out of crate zero, so those should be expected to be all 0’s as well. These are followed by 2 constant zero bits. And finally there are five bits that tell how many data words follow the header word. The rest of the bits have no meaning (should always be 0’s).

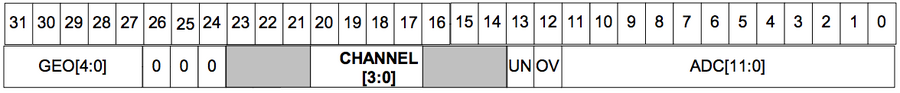

QDC Data Word[edit | edit source]

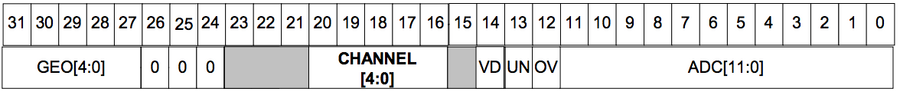

TDC Data Word[edit | edit source]

For a data word, the geo bits are the same. The three bits should read 000 to mean it is a data word. There will be three unimportant bits (again 0’s), followed by five channel bits. There will be one unimportant bit, and then the QDC will have a second unimportant bit, but the TDC will have a bit to determine valid data. If that valid bit is a 1 then the data is good. For both machines, there will be bits to determine whether the data is underthreshold or in overflow in that order. For our purposes, these bits should always be 0’s meaning that it is not underthreshold nor is it in overflow condition. The last 12 bits is the data itself.

The closing word is simply a constant telling the analyzer to stop parsing when it reads this word.

Example[edit | edit source]

Here is the word from the previous sections, to break it down in these meanings:

11111 000 000 0000 001 00 000010000001

The first five bits are 11111, as expected. The next three are 000, meaning it is a data word. Three unimportant bits. It is coming from channel zero. Three unimportant bits. Not it underthreshold nor overflow. And then the last twelve bits are the data.